Precast Concrete Components

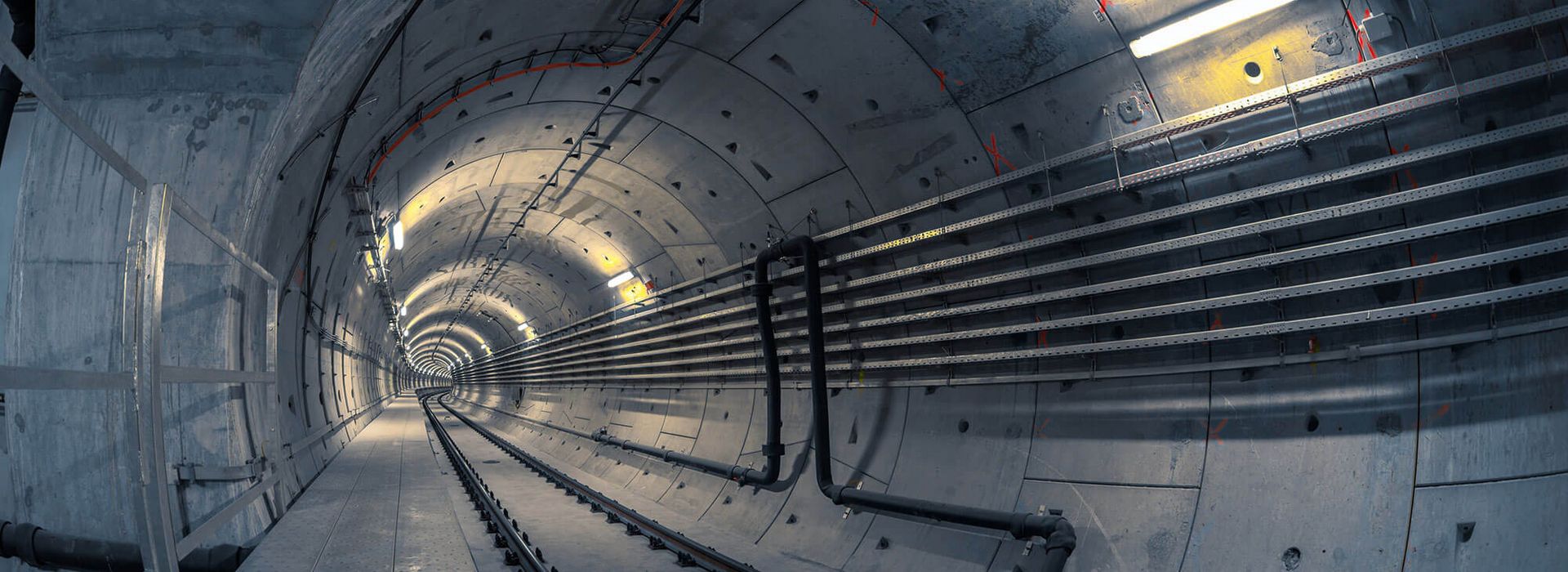

The precast concrete industry is evolving rapidly. With increasing demands for load-bearing capacity, torsional stiffness, strength, dimensional accuracy, and surface quality, precast components are becoming ever more complex — both in function and geometry. Whether in tunnel and rail construction with concrete pipes, tunnel lining segments, and track slabs, or in bridge and building construction, precast elements are setting new standards in efficiency and design. Especially freeform surfaces now offer almost limitless possibilities.

This architectural freedom demands the highest precision in quality control. The accurate measurement of the shape and position of complex components is essential for verifying structural load-bearing capacity — and thereby ensuring the functionality and safety of the entire structure.

With decades of experience and cutting-edge metrology, we capture form and positional tolerances in real time — directly on the construction site or in the production facility. We process and visualize measurement results graphically, enabling immediate adjustments to formwork. This allows for fast decision-making, avoids costly rework, and ensures the highest quality right within the production process.

Our Experience and Expertise

![[Translate to en:] Logo](https://messtechnik.trigonos.at/fileadmin/user_upload/trigonos-19-logo-4c.jpg)