Automotive Industry

Increasing demands on product quality, combined with intense cost pressure and high cycle times, define the environment in which the automotive industry operates. Manufacturers aim to produce vehicles based on customer orders using build-to-order concepts while still enabling mass customization. This is achieved through a high degree of automation and uninterrupted line production.

The functionality of individual components and assemblies depends heavily on compliance with defined specifications, which are continuously refined and pushed to their limits. Ever more complex components lead to increasingly complex tooling, which must also meet these strict requirements.

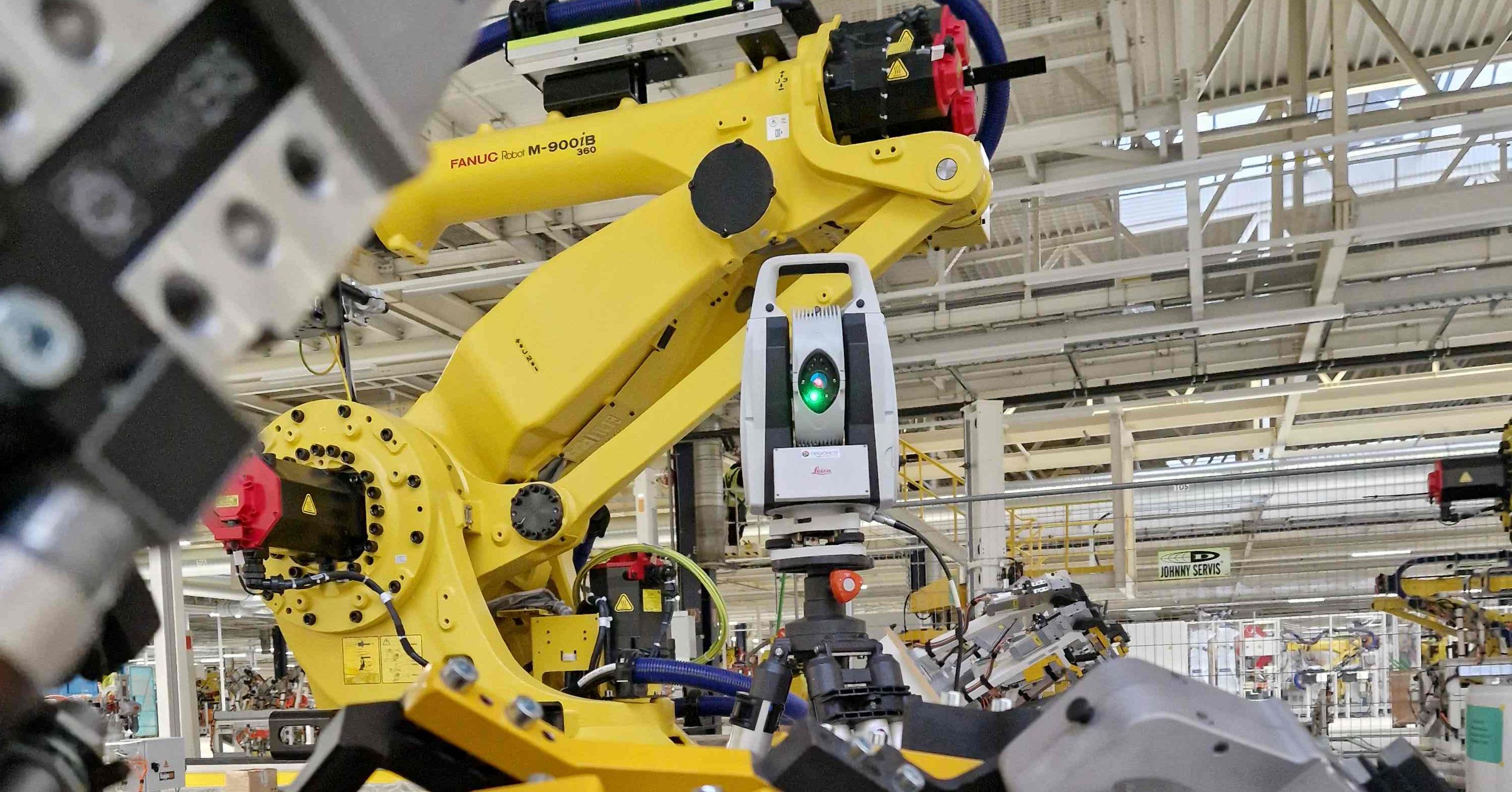

With our advanced metrology systems, we support the entire lifecycle of high-performance production lines. This begins with floor layout marking for fast and precise installation of production systems — implemented with maximum accuracy using automated robots. At the same time, tooling such as fixtures, grippers, framers, and geo pallets is manufactured in tool shops and subsequently aligned, inspected, and documented by our team in compliance with all specifications.

After successful tool installation, our highly qualified specialists verify conditions directly on site and perform final adjustments. During production, we carry out as-built measurements, enabling early identification of wear or potential error sources before they impact the process. To further optimize production performance, we determine static and dynamic parameters of production robots directly at the customer site. With decades of experience, we accompany the entire lifecycle of production systems — ensuring quality and increasing efficiency.

Request consulting nowExperience and Expertise

![[Translate to en:] Logo](https://messtechnik.trigonos.at/fileadmin/user_upload/trigonos-19-logo-4c.jpg)